Surface Roughness Chart: A Complete Guide to Symbols, Values, and Measurement

Surface finish is more than just a cosmetic detail; it is a critical aspect of engineering that directly impacts a product’s functionality, durability, and performance. For instance, specific levels of roughness can be essential for improving adhesion or ensuring a proper seal. This guide will walk you through the fundamentals of surface texture, from what it is to how it’s measured and specified.

You’ll gain a clear understanding of surface roughness charts, common symbols, and their meanings.

This will help you to effectively communicate your requirements in technical drawings and throughout the manufacturing process. Whether you’re a design engineer, a machinist, or a procurement specialist, this guide will provide practical knowledge for your projects.

What is Surface Finish?

Surface finish, also known as surface texture, refers to the overall condition of a product’s surface.It’s defined by three main characteristics:

- Roughness: These are the fine, microscopic irregularities on a surface that result from a manufacturing process, like the marks from a cutting tool or the grit of a grinding wheel.When people in the industry talk about “surface finish,” they are most often referring to surface roughness.

- Waviness: This refers to the larger, more widely spaced undulations on a surface. These are often caused by things like machine vibration or warping.

- Lay: This is the direction of the predominant surface pattern, which is usually determined by the manufacturing method used.

Why is Surface Finish So Important?

The surface finish of a component plays a vital role in how it performs in its intended environment. It can affect everything from friction and wear resistance to how well a part can be sealed. Here are some of the key reasons why surface finish is so critical in engineering:

Corrosion and Chemical Resistance: A smoother surface generally has better resistance to corrosion and chemical attack.

Visual Appeal: The finish of a product contributes significantly to its aesthetic quality.

Adhesion of Coatings and Paints: The texture of a surface has a direct impact on how well paints, coatings, and adhesives will stick to it.

Elimination of Surface Defects: Finishing processes can remove or reduce surface flaws that could compromise a part’s integrity.

Electrical Conductivity: In some applications, surface finish can be tailored to enhance electrical conductivity.

Friction and Wear: A smoother surface generally reduces friction between moving parts, which minimizes wear and heat generation.

How to Measure Surface Roughness

Because the irregularities in a surface are often too small to be seen with the naked eye, specialized instruments are needed for measurement.

The most common parameter for surface roughness is Ra, which stands for Roughness Average.

It represents the arithmetic average of the surface’s peaks and valleys measured from a mean line. There are several methods for measuring surface roughness, which can be broadly categorized as follows:

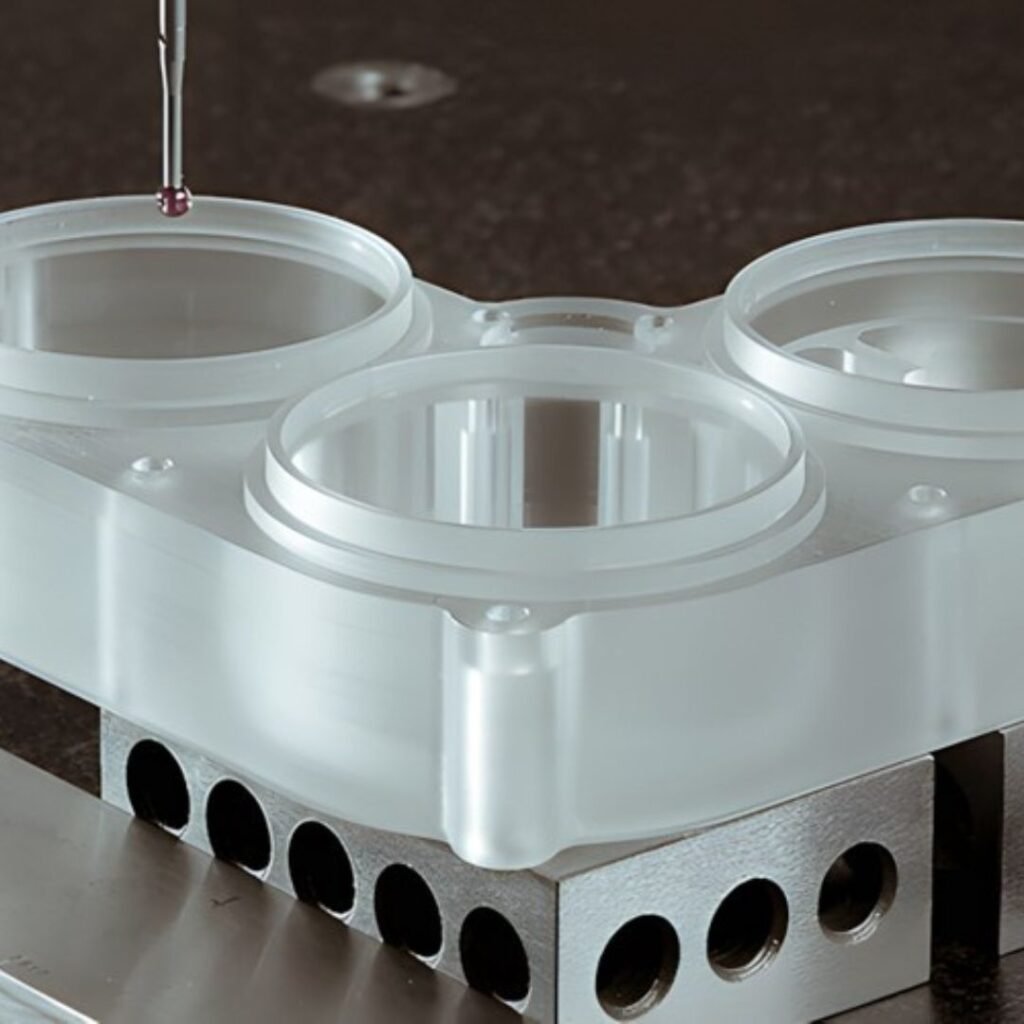

Direct Measurement : These methods use a stylus that is drawn across the surface to record its profile. This is a highly accurate way to measure roughness.

Non-Contact Methods : These methods use light or sound to measure the surface without touching it. Optical profilometry and atomic force microscopy are examples of non-contact methods.

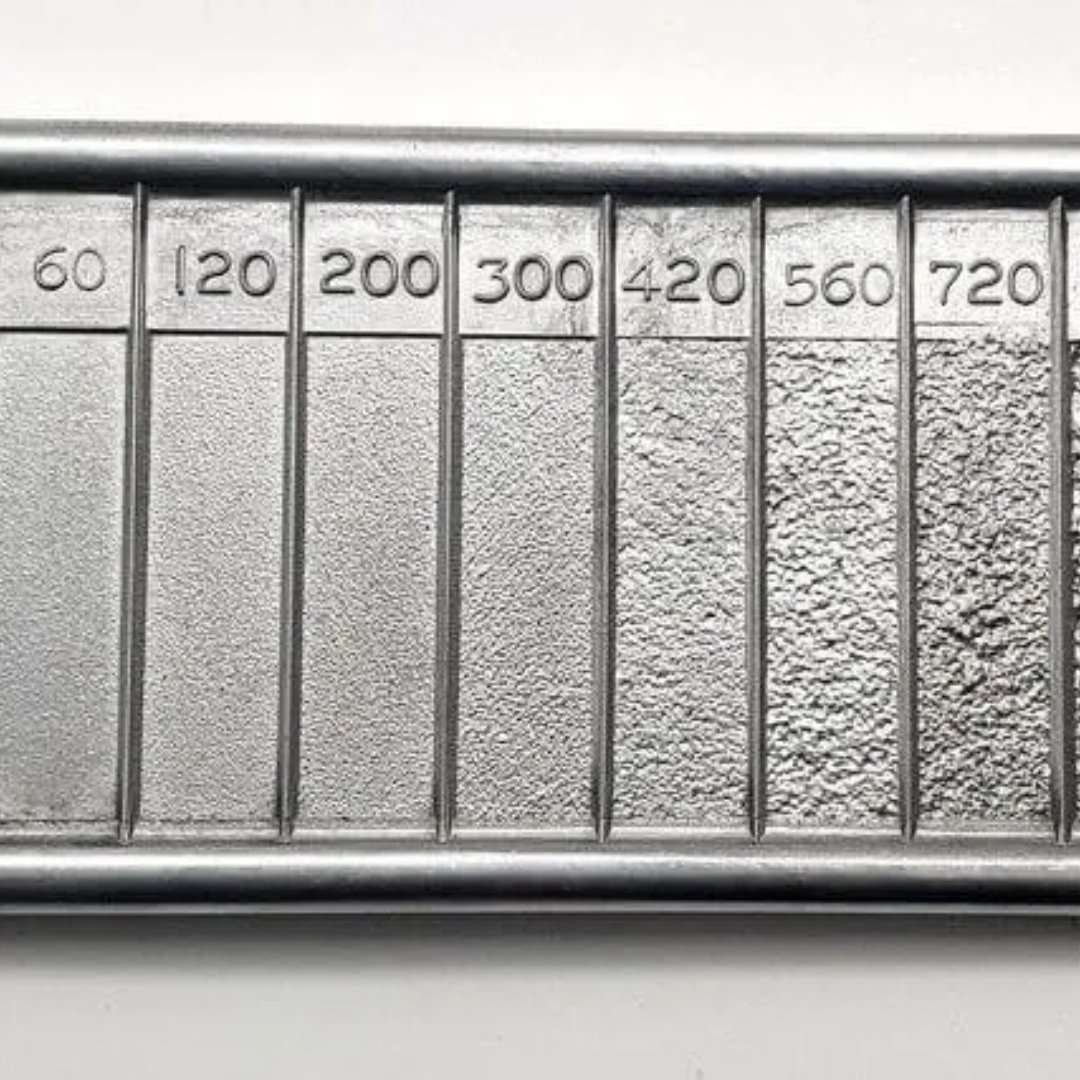

Comparison Methods : In this technique, the surface is visually and tactilely compared to a reference sample with a known surface roughness.

In-Process Methods : These methods are used to monitor surface roughness during the manufacturing process itself.

Understanding Surface Roughness Symbols

In engineering drawings, a standardized set of symbols is used to communicate surface finish requirements.

This ensures that everyone, from the designer to the machinist, understands the specifications. Here are some of the most common symbols and what they mean:

Ra (Roughness Average): The most widely used parameter, representing the average roughness of a surface.

Rz (Average Maximum Height of the Profile): This parameter measures the average of the five largest differences between peaks and valleys. It is more sensitive to extreme variations than Ra.

Rmax (Maximum Roughness Depth): This is the vertical distance between the highest peak and the lowest valley within a single sampling length. It is useful for identifying individual defects like scratches.

The Cost of Surface Finish

It’s important to be aware that achieving a smoother surface finish generally increases the manufacturing cost.

This is because it often requires more precise and time-consuming processes, such as grinding, polishing, or lapping.

Therefore, it is crucial to specify a surface finish that is appropriate for the application without being unnecessarily costly.

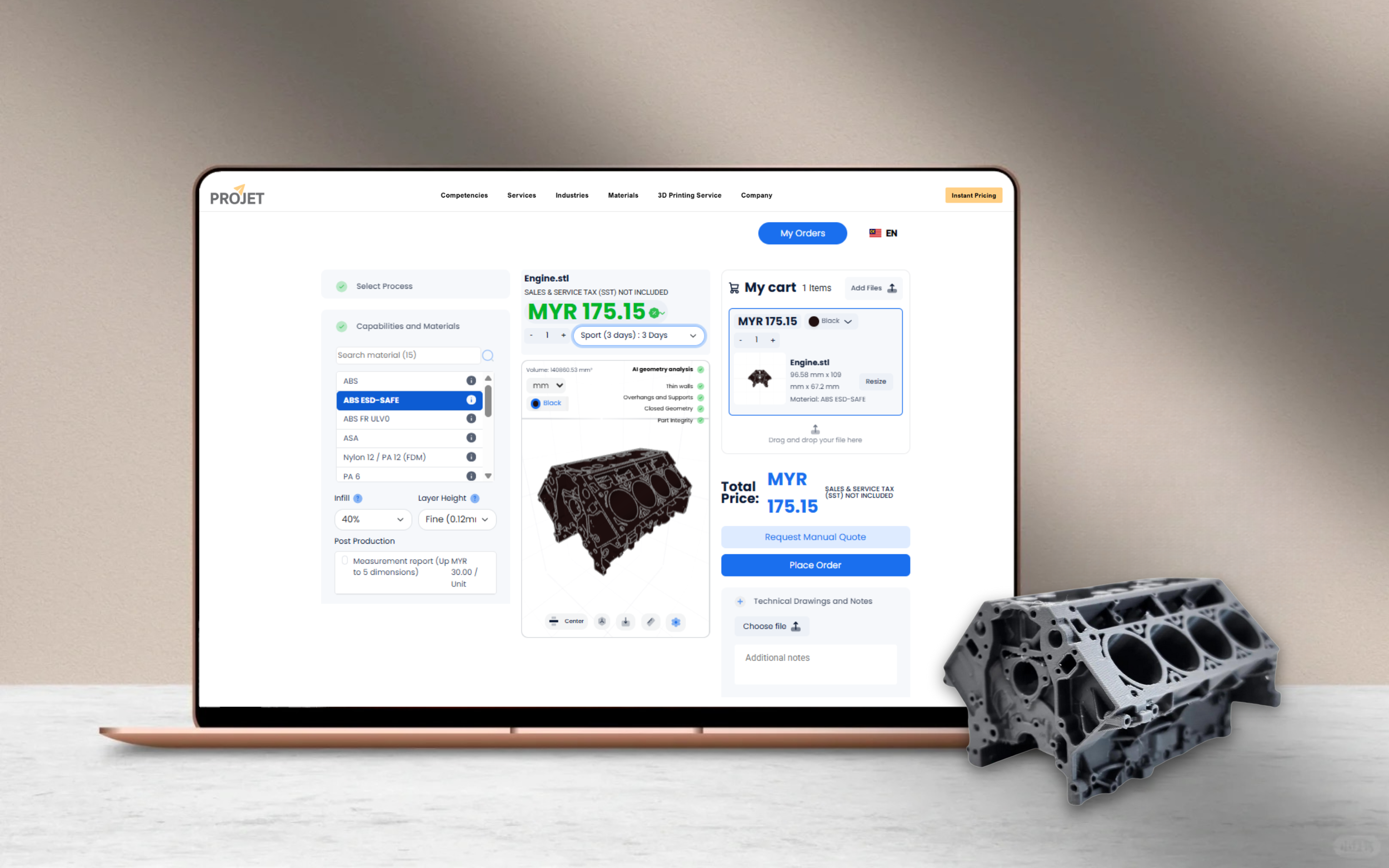

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Which Method Should You Choose?

Both CNC machining and injection molding have unique strengths. Choose based on what you need:

Choose CNC Machining if you need:

- Low-volume production

- Rapid prototyping

- Tight tolerances

- Strong material properties

- Design flexibility and fast revisions

Choose Injection Molding if you need:

- High-volume production

- Low cost per part

- Repeatability and consistency

- Complex molded features

- Long-term manufacturing scalability

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success.

Here’s why companies across electronics, automotive, consumer products, aerospace, and medical industries trust Projet:

✔ One Stop Solution

✔ Engineering Expertise You Can Count On

✔ Flexible Production Volumes

✔ Fast Quotes & Rapid Turnaround

✔ Your Manufacturing Partner, Not Just a Supplier

3D Printing Services

Instant Price