Low Volume Production

Low volume manufacturing produces 1–1,000 units, ideal for custom or niche products without the need for large-scale production. Low volume manufacturing is cost-effective for small businesses, startups, or companies who want to test new products before scaling up production. It allows for design flexibility, customisation, and rapid prototyping.

What is Low Volume Production?

Low volume manufacturing refers to the process of producing a limited number of parts or products, usually ranging from a few units to several thousand. Unlike mass production, which focuses on high-volume output, low volume manufacturing is designed for small batch production, rapid prototyping, and custom manufacturing needs.

This approach is widely used across industries such as automotive, aerospace, medical devices, and consumer electronics, where flexibility, speed, and cost efficiency are crucial.

Low volume production offers several advantages over traditional high-volume methods:

- Faster time-to-market : Ideal for testing new products before full-scale production.

- Cost efficiency : Avoids the high upfront costs of large-scale tooling.

- Flexibility : Supports design changes, customization, and short production runs.

- Risk reduction : Helps businesses validate demand before committing to mass production.

A Bridge from Prototyping to Production

Low volume manufacturing serves as the perfect bridge between prototype development and high volume production. It allows businesses to scale gradually while reducing risks and optimizing designs before committing to large-scale manufacturing.

- Quality at Speed: Small batch production enables rapid manufacturing without compromising product quality. This accelerates the path from concept to market launch.

- Minimized Inventory Risk : Instead of tying up capital in large stockpiles, companies can produce only what is needed. This approach reduces storage costs and prevents excess inventory.

- Increased Supply Chain Flexibility : By producing in smaller quantities, businesses can adapt quickly to changes in market demand, customer feedback, or evolving design requirements.

- Simplified and Accelerated Product Testing : Producing limited runs makes it easier to test designs, gather customer feedback, and implement improvements before scaling to full production.

Technologies are used low volume production

Low volume manufacturing relies on a variety of advanced production methods that balance cost efficiency, speed, and flexibility. Below are the most common technologies used for small batch production:

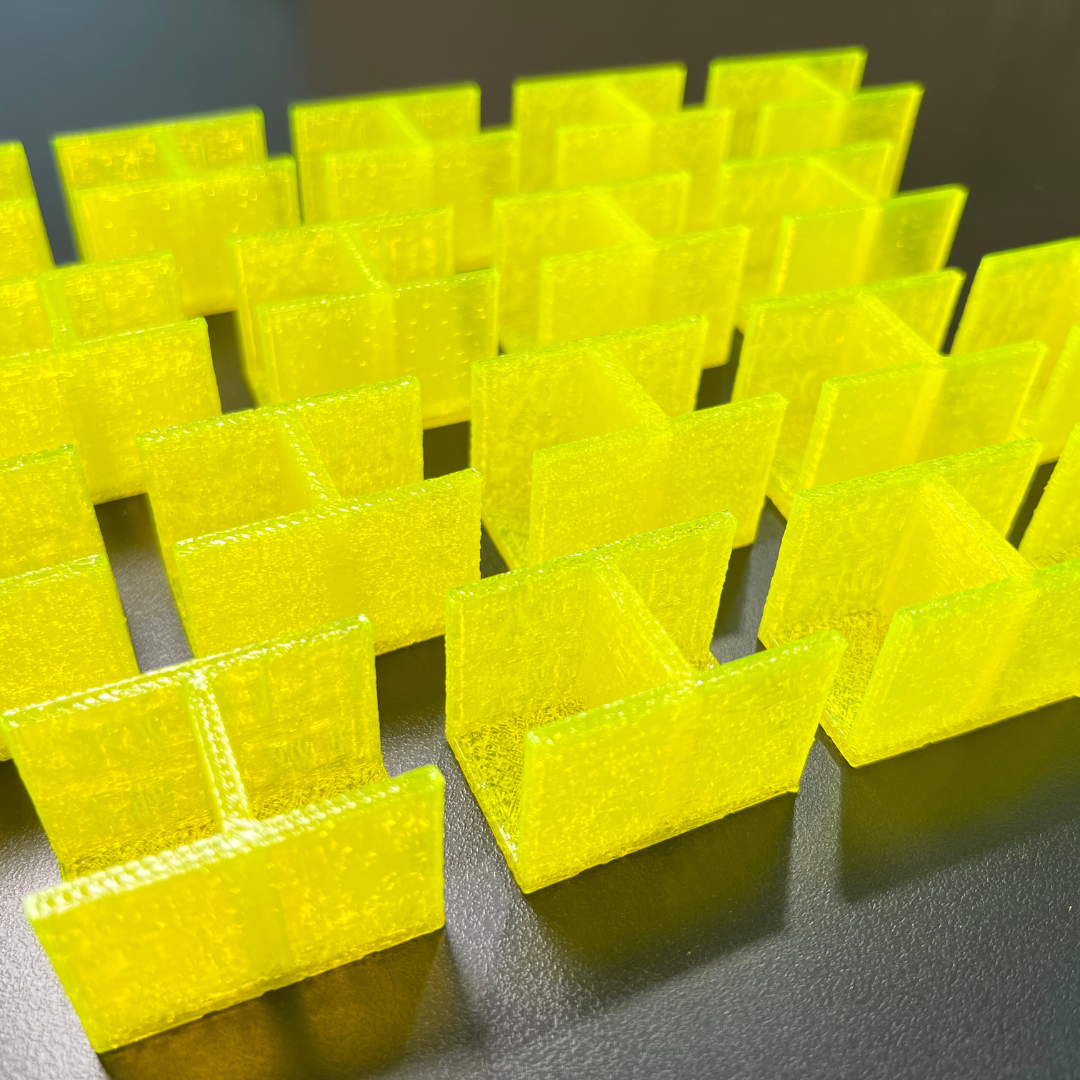

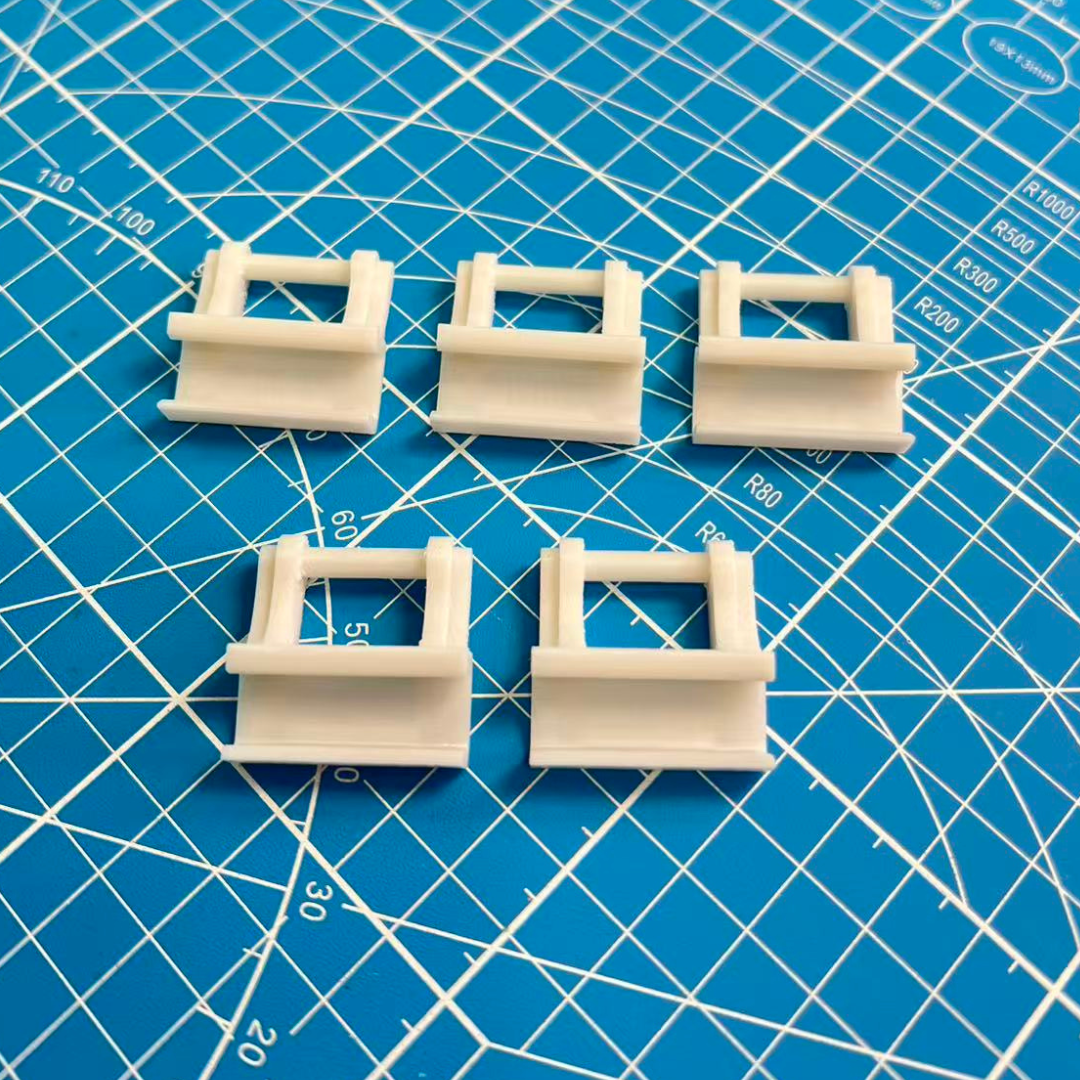

- 3D Printing : 3D printing, also known as additive manufacturing, is ideal for producing custom parts in small quantities. It requires minimal setup time and reduces tooling costs, making it perfect for rapid prototyping, functional testing, and on-demand production.

- CNC Machining : CNC machining creates parts by subtracting material from a solid block of raw material. It offers precision, durability, and cost-effectiveness for low volume production runs, especially when working with metals and plastics.

- Vacuum Casting : Vacuum casting is used to produce small batches of high-quality parts using silicone moulds and polyurethane resins. This method is cost-effective for replicating prototypes, creating functional models, and delivering short-run production with a professional finish.

- Laser Cutting : Laser cutting is widely used for cutting, engraving, and shaping materials such as metal, plastic, wood, and composites. Its speed, accuracy, and low setup cost make it an excellent choice for prototyping and small production batches.

Rapid prototyping to volume production

Projet actively revolutionizing with technology – propelling entire industries forward by showcasing its impact in every stage, from rapid prototypes to crafting end-use parts that redefine efficiency.

This isn’t just a vision – it’s the reality we’re shaping. We’ve pioneered a groundbreaking solution that revolutionizes how parts are designed and prototyped. By leveraging the unique abilities, we’re able to speed up product development, offer cost-effective low-volume manufacturing with no minimum order quantity, and shore up manufacturing workflows.

Volume production

Time is money, and we’re saving you both. Think of us as production time machine. We’ll warp 3D printing volume orders from months to weeks, leaving our clients with more time to focus on what matters most.

- High-quality finish, meets market standards

- Durable and long-lasting materials specifications

- Low mix high volume/ high mix low volume

- Custom end-use parts/ mass customization

Industries That Rely on Low Volume Manufacturing

Low volume manufacturing is widely used across industries where customization, precision, and small batch production are critical. Below are the industries that most commonly employ this manufacturing approach:

Aerospace and Defence

The aerospace and defence industry often requires specialized, complex, and highly engineered components. Since production volumes are typically small, low volume manufacturing provides the flexibility and precision needed for aircraft parts, defence equipment, and mission-critical components.

Automotive

In the automotive sector, low volume production supports prototype development, custom parts, and specialty vehicles. Manufacturers use it to test designs, create aftermarket parts, and produce limited edition vehicles without committing to mass production.

Medical

Medical device manufacturing demands strict precision, customization, and rigorous testing. Low volume manufacturing enables the production of small batches of surgical instruments, implants, diagnostic equipment, and custom prosthetics, helping companies validate performance before full-scale production.

Electronics

The electronics industry relies on low volume manufacturing for prototyping, custom components, and short-run production of niche devices. This approach allows for rapid innovation and market testing in a field where technology evolves quickly.

Consumer Goods

In the consumer goods industry, companies often use low volume production to create limited edition products, niche-market items, and customized goods. This approach helps brands test demand and engage customers with exclusive offerings.

Benefits of Low Volume Manufacturing

Low volume manufacturing offers businesses a practical and cost-effective alternative to mass production. By producing smaller quantities, companies gain the flexibility to adapt quickly, reduce risks, and optimize resources. Below are the key benefits:

Reduced Upfront Costs

Low volume manufacturing avoids the need for expensive production equipment and high minimum order quantities (MOQs). This reduces initial capital expenditure, making production more accessible for startups, small businesses, and product launches.

Flexibility in Design and Production

Companies can easily modify product designs, incorporate customer feedback, and introduce new features during production. This agility enables businesses to quickly respond to market changes and customer demands.

Customization

Low volume manufacturing is ideal for producing custom or niche products tailored to specific customer requirements, offering a competitive advantage in industries where personalization matters.

Faster Time to Market

Producing smaller batches means shorter turnaround times, allowing companies to bring products to market quickly. This speed is particularly valuable in fast-moving industries or for products with short lifecycles.

Reduced Inventory Risks

By manufacturing only what is needed, businesses minimize the risk of overproduction and excess inventory. This reduces storage costs and supports lean, demand-driven production strategies.

Sustainability and Reduced Waste

Smaller batch sizes help minimize material waste and reduce overproduction, aligning with sustainable manufacturing practices increasingly valued by both consumers and regulators.

Utilisation of Advanced Manufacturing Technologies

Low volume manufacturers often use cutting-edge technologies such as 3D printing, CNC machining, laser cutting, and vacuum casting. These methods deliver high precision, speed, and quality even for small production runs.

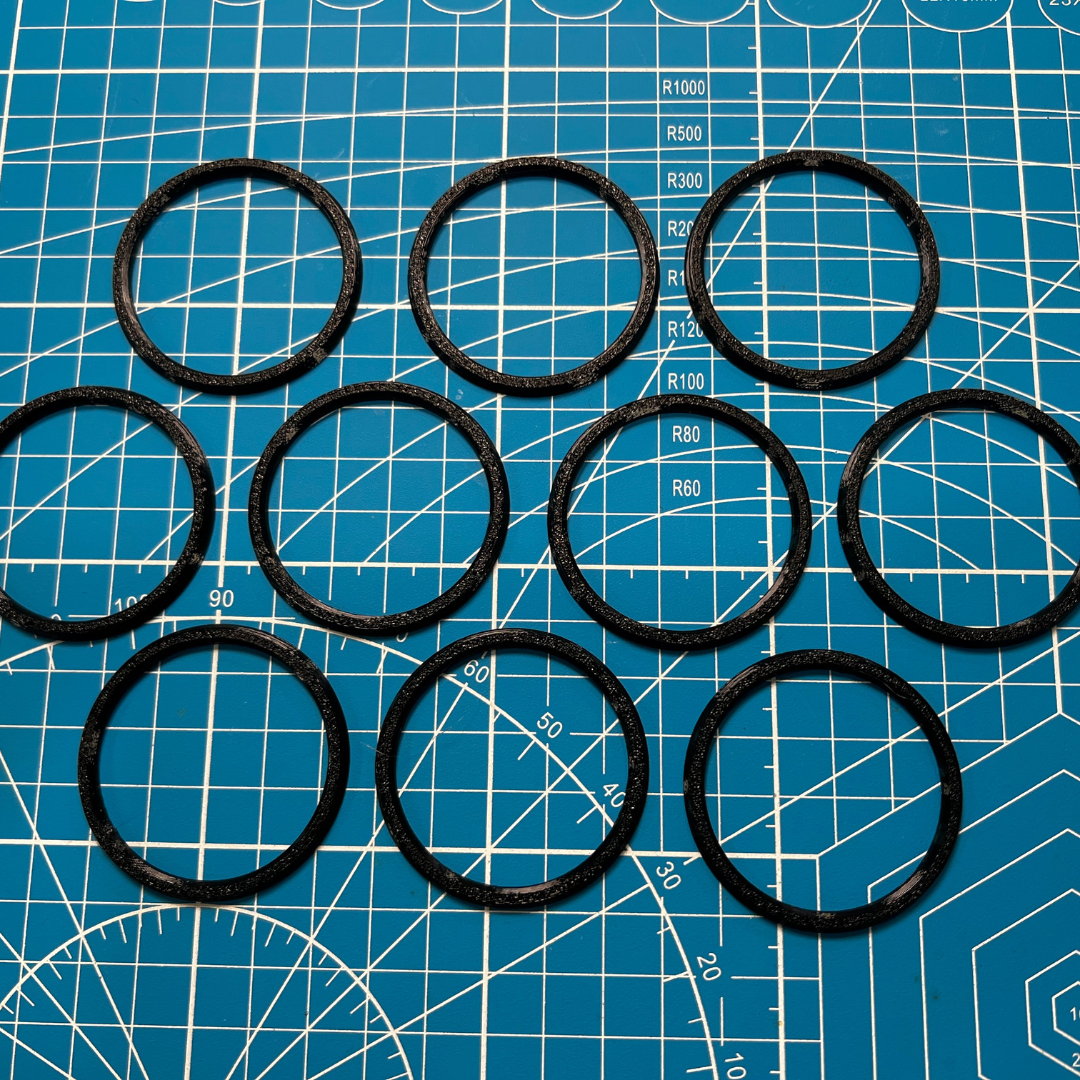

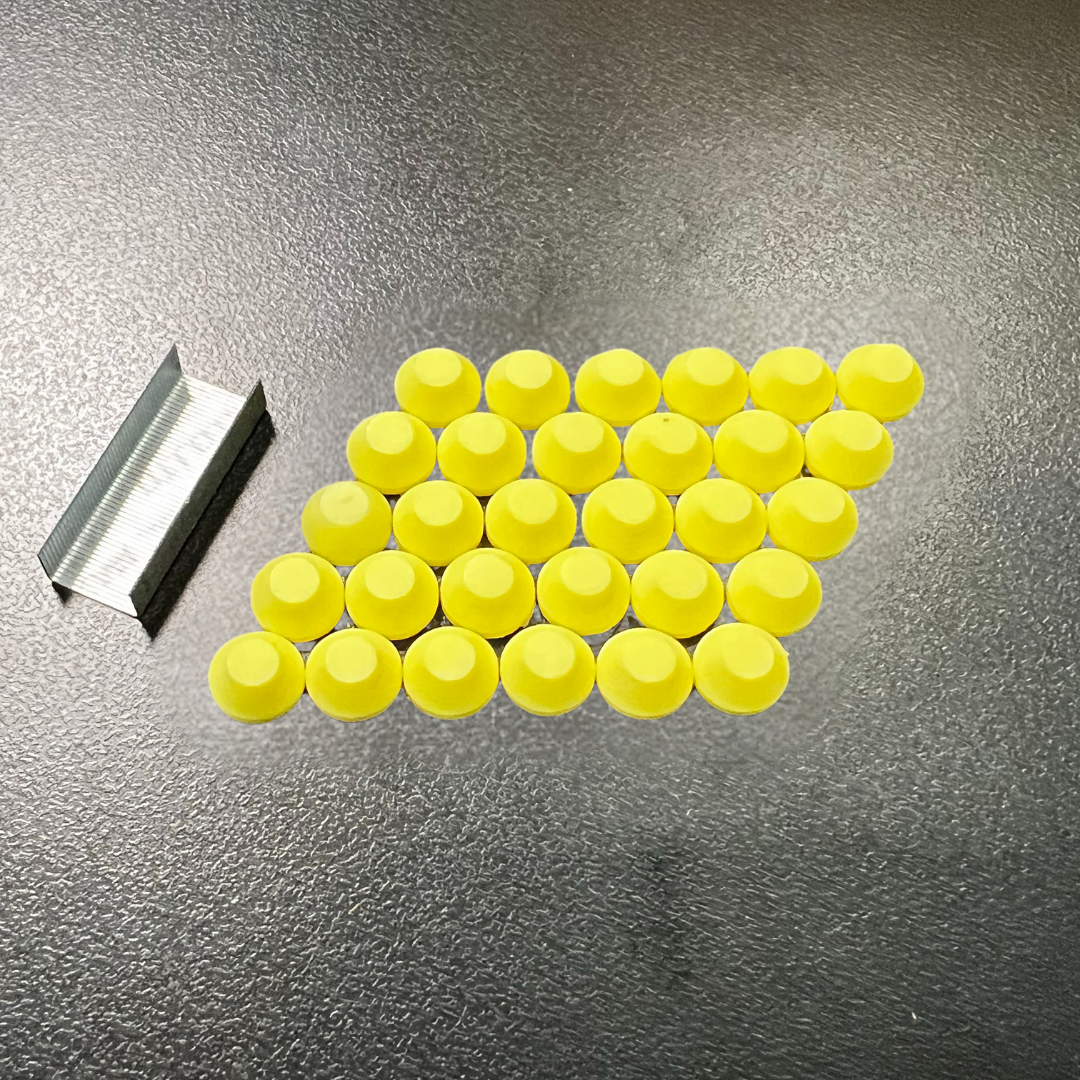

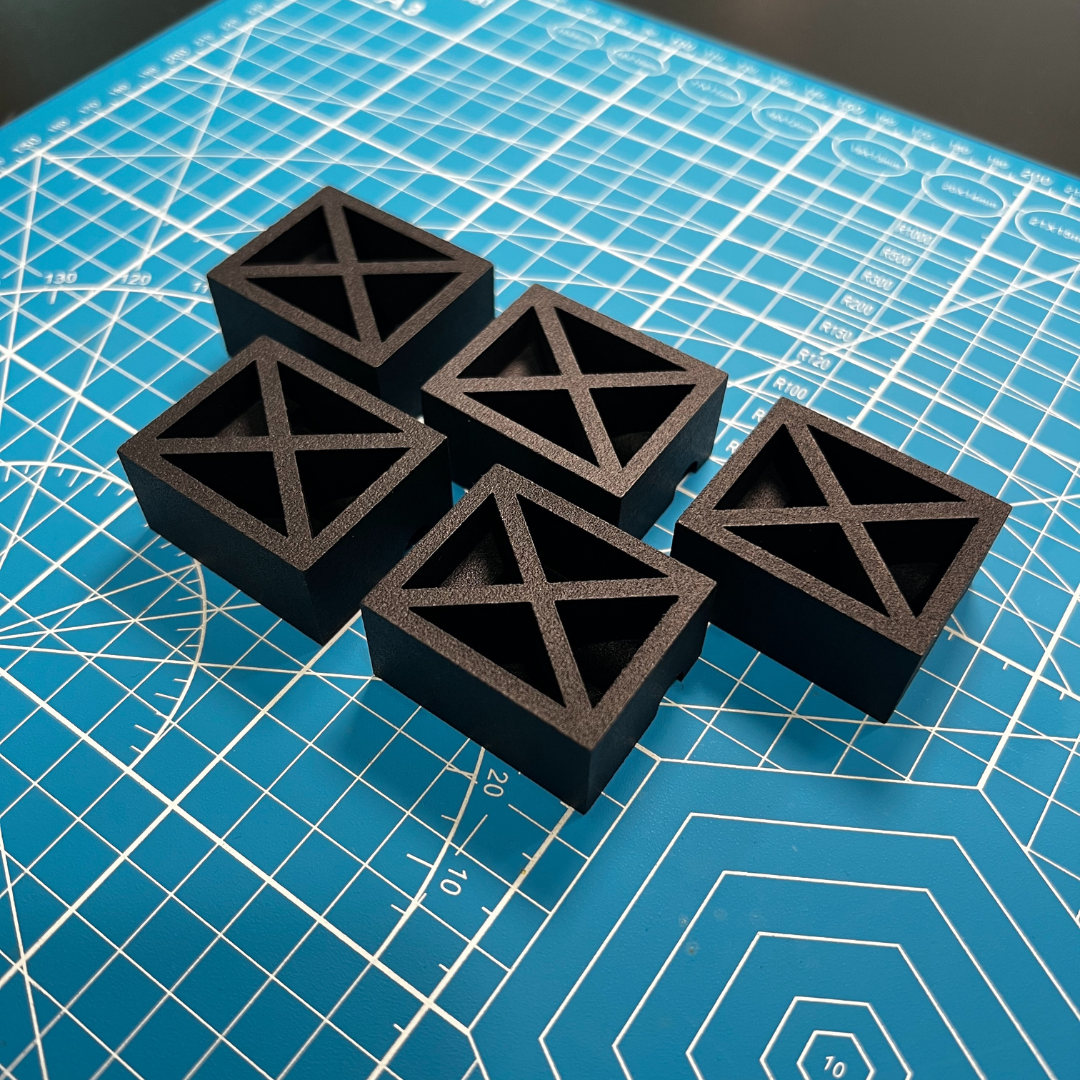

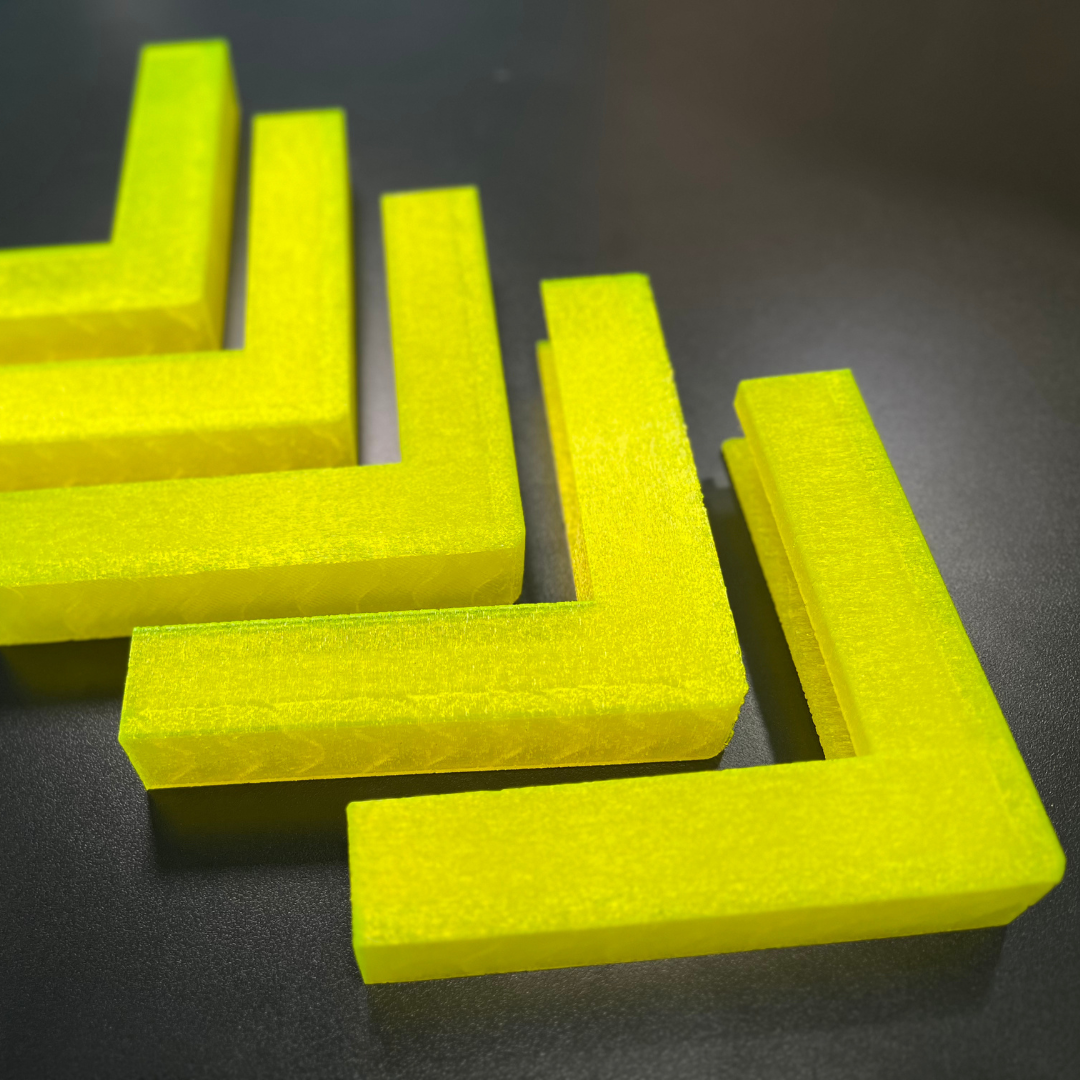

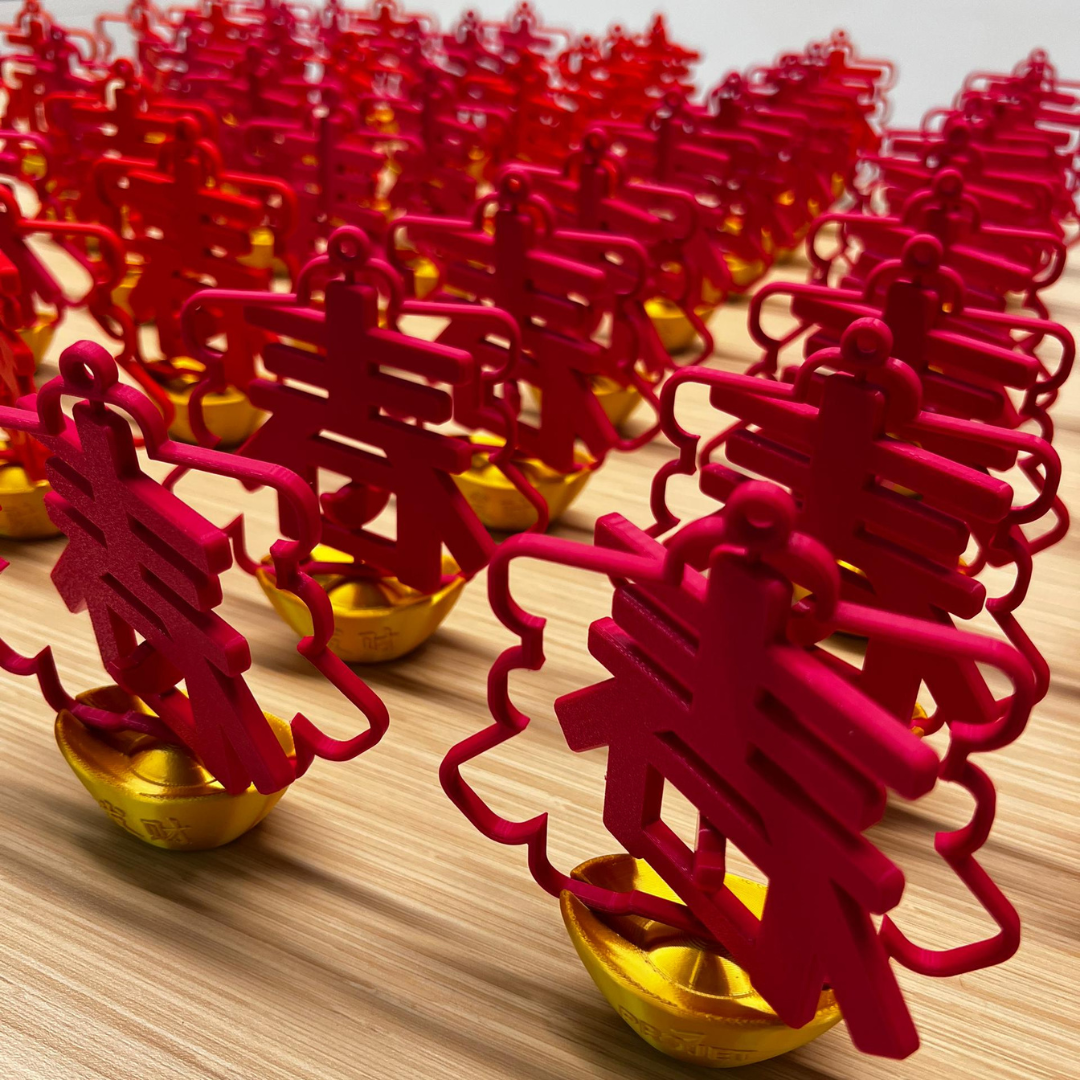

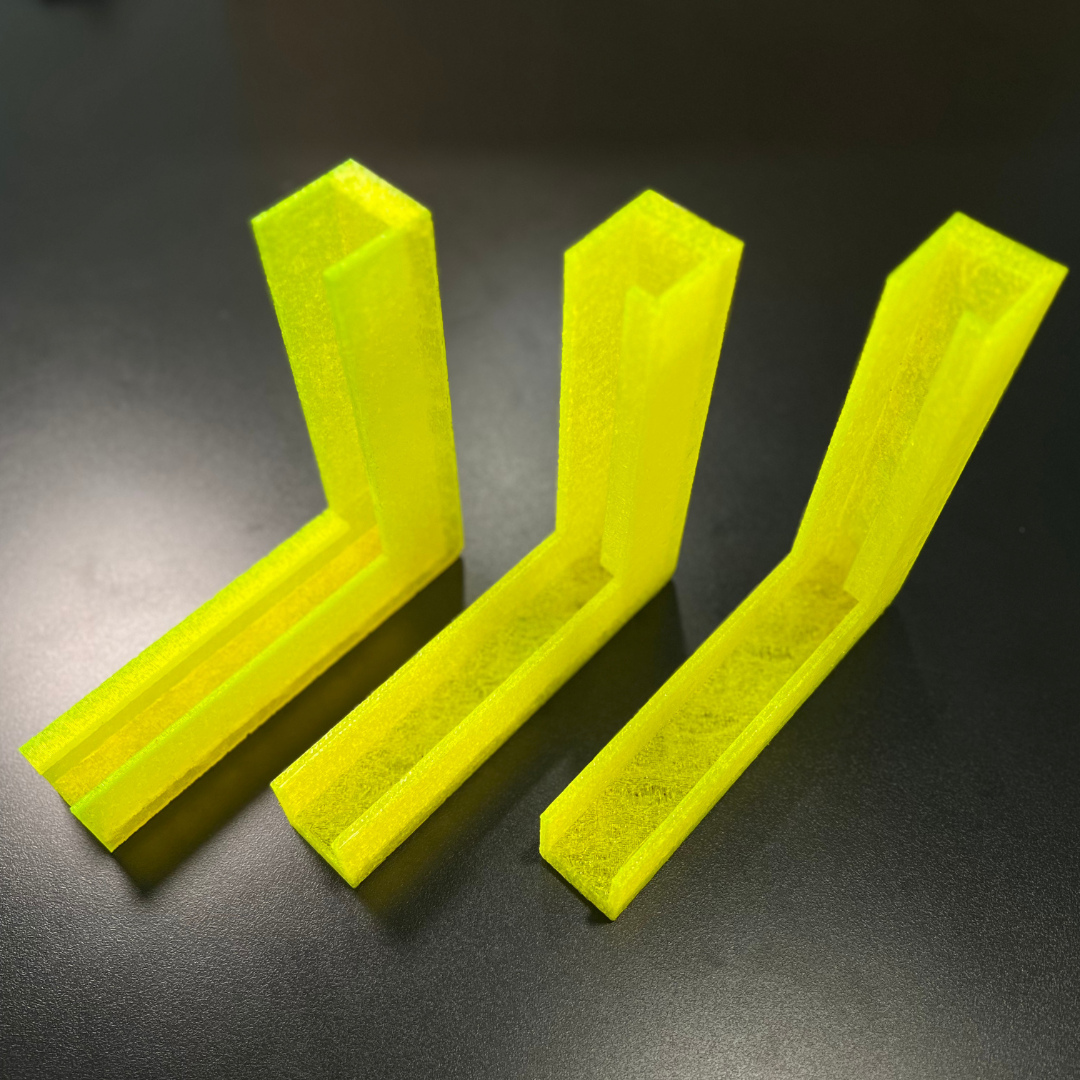

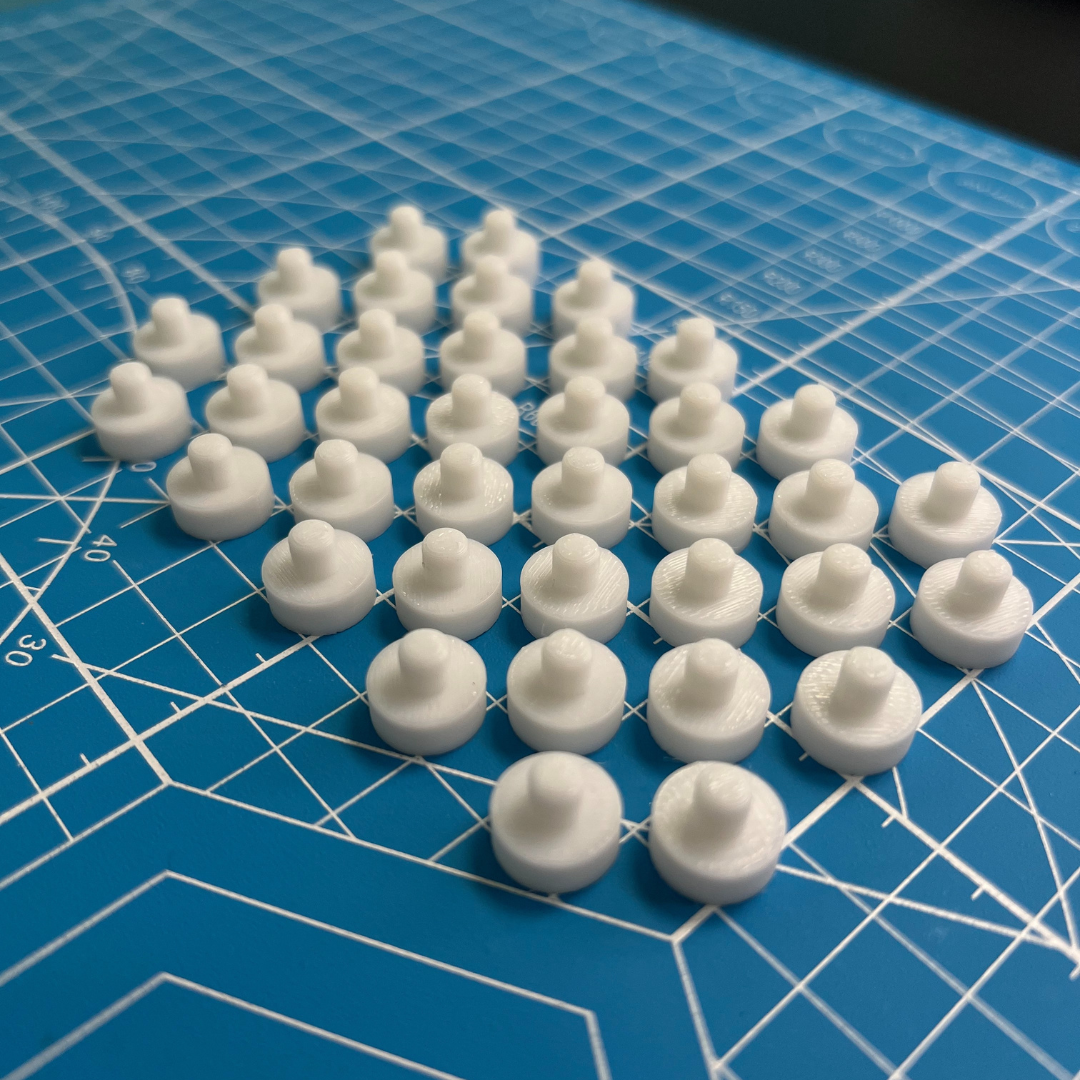

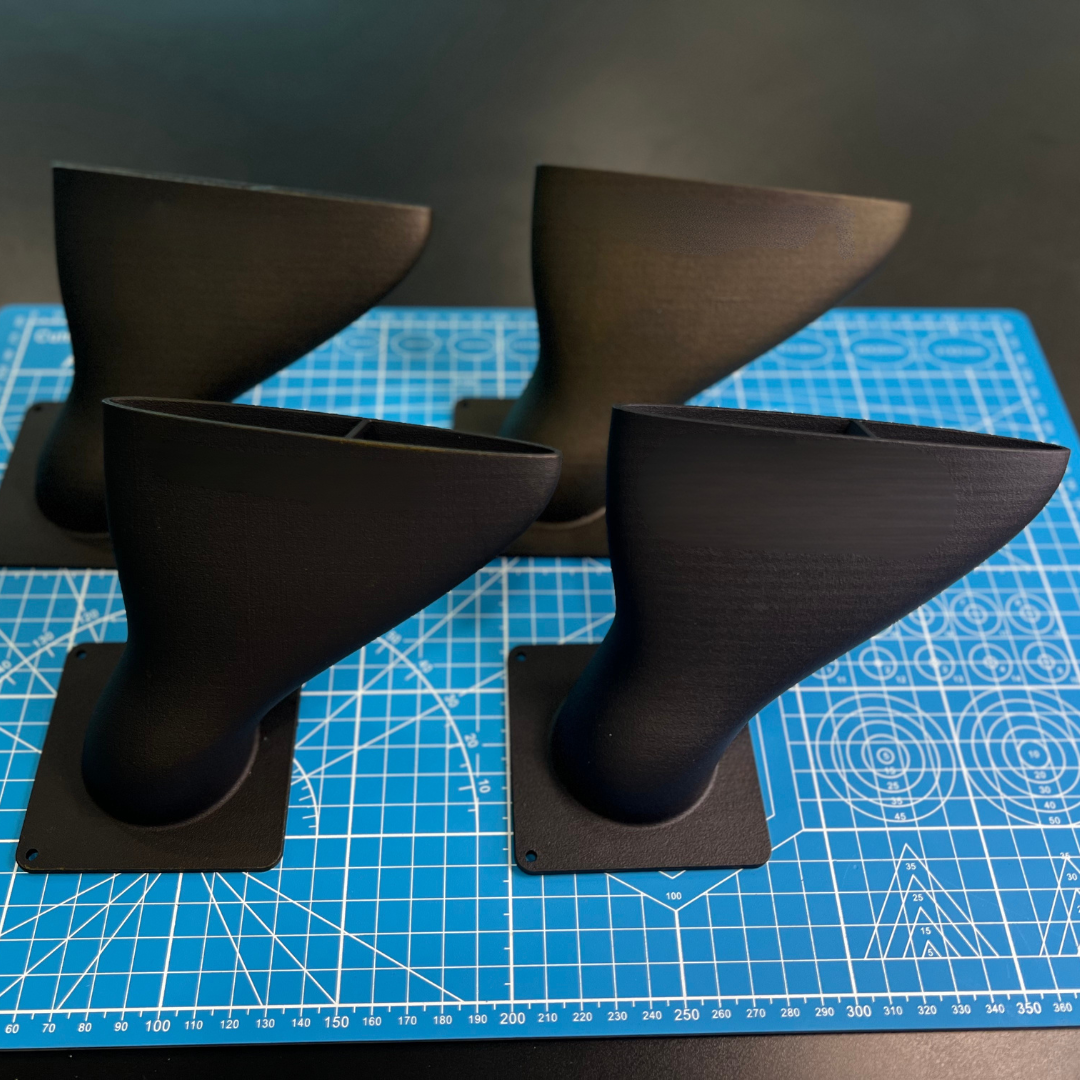

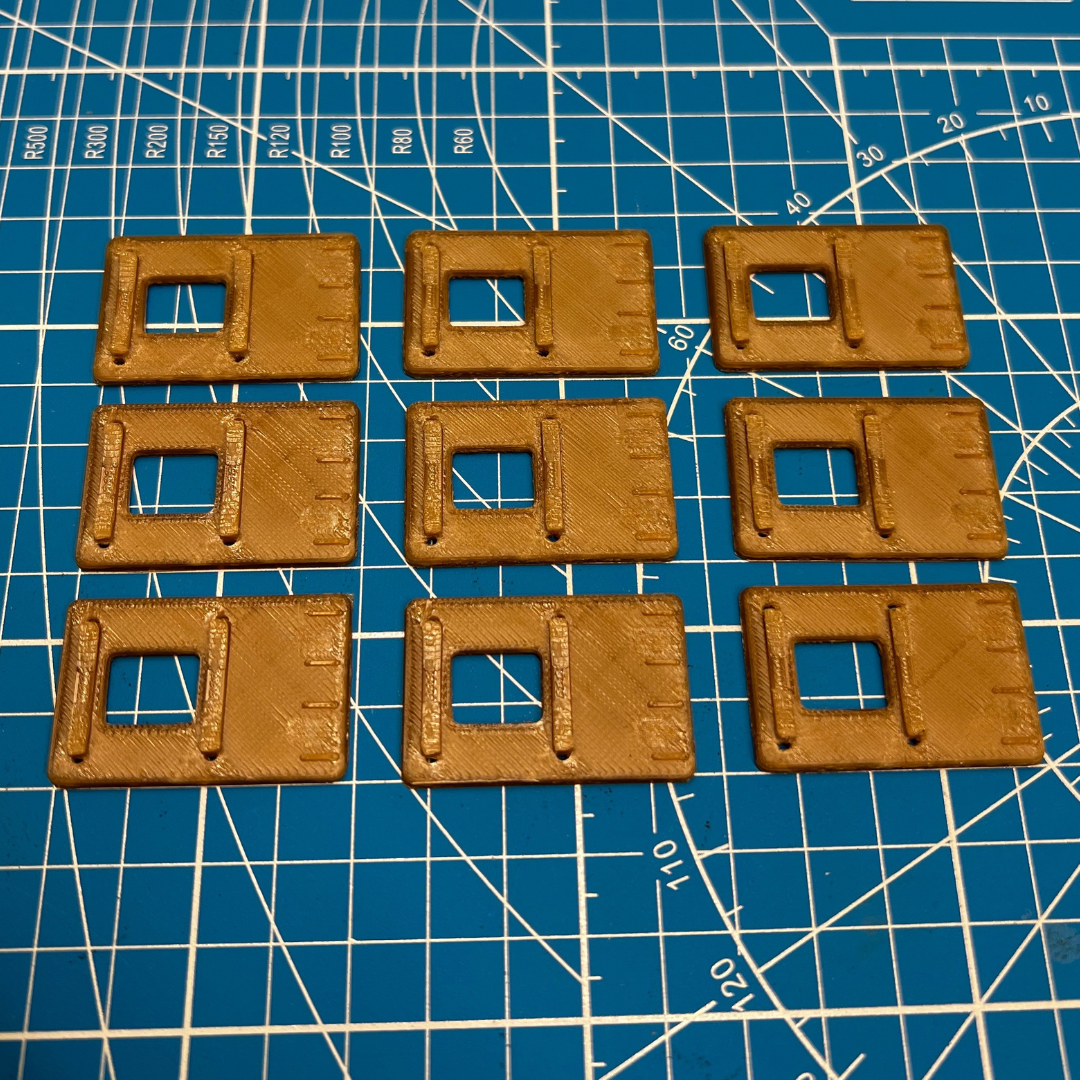

Gallery

Our competencies

We are a highly dependable mechanical powerhouse with an extensive array of additive manufacturing (3D Printing) & subtractive manufacturing capabilities. Catering from one-off prototyping to low-volume production, we offer solutions that span from basic to industrial, including cosmetic finishing manufacturing.

3D Printing

SLS,SLA,SLM,FDM,MJF,PµSL

- Tolerances accuracy ± 0.02 mm

- Class 1 surface finishing

- Engineering grade material

Laser Cutting

CO2 Laser

- Bending, welding

- Stainless steel, aluminium

- Thermoplastic, tapes & gaskets

- Cutting, boring, engraving, etching

Vacuum Casting

Urethane Casting

- Material flexibility

- High transparency

- Production-like parts

CNC Machining

Milling, Turning

- Tolerances down to ± 0.03 mm

- 3 & 5 axis

- Anodizing, powder coating

- Wide range of material

Start your next project with us today

Manufacturing limitless possibilities with industrial fabrication solutions.