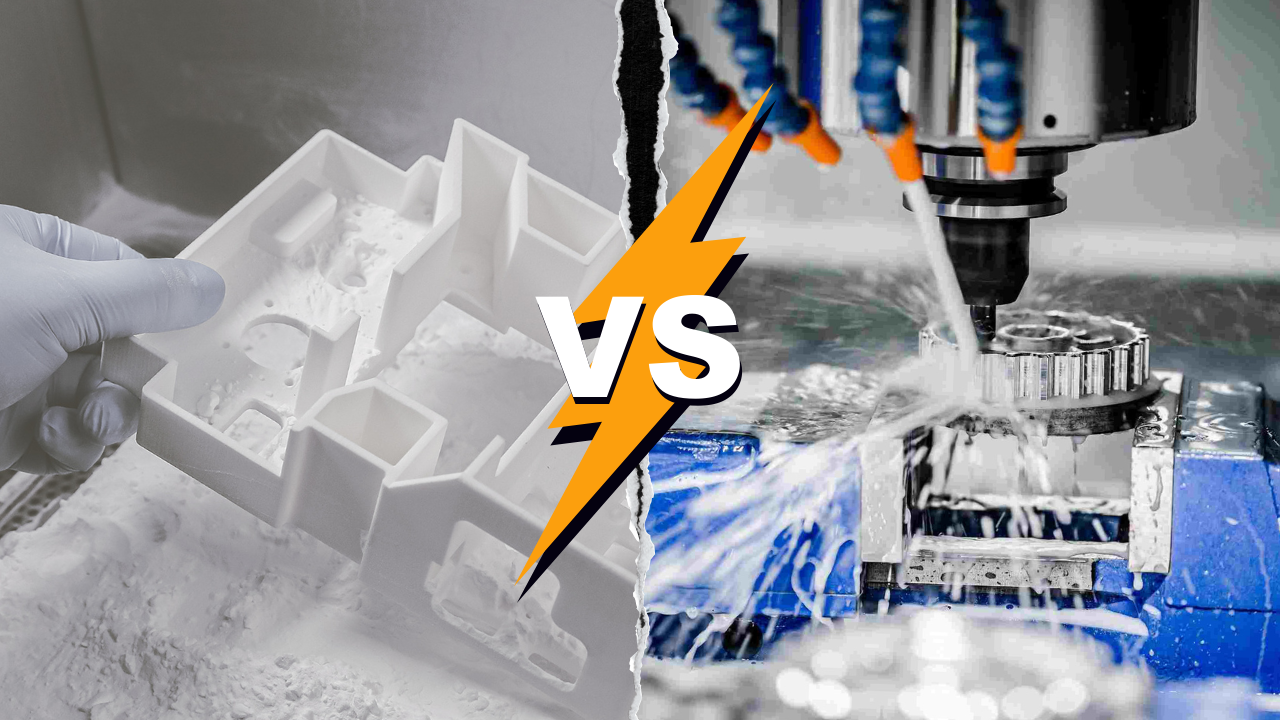

When it comes to modern manufacturing, two of the most common production methods are CNC machining and 3D printing. Both technologies play a critical role in low volume manufacturing, rapid prototyping, and custom part production, but they differ significantly in process, materials, precision, and cost.

CNC machining is a subtractive manufacturing method that excels in precision, durability, and material versatility, while 3D printing (additive manufacturing) is known for its speed, design flexibility, and low setup costs.

So, how do you decide which method is right for your part? In this guide, we’ll compare CNC machining vs 3D printing across:

Subtractive vs. Additive Manufacturing

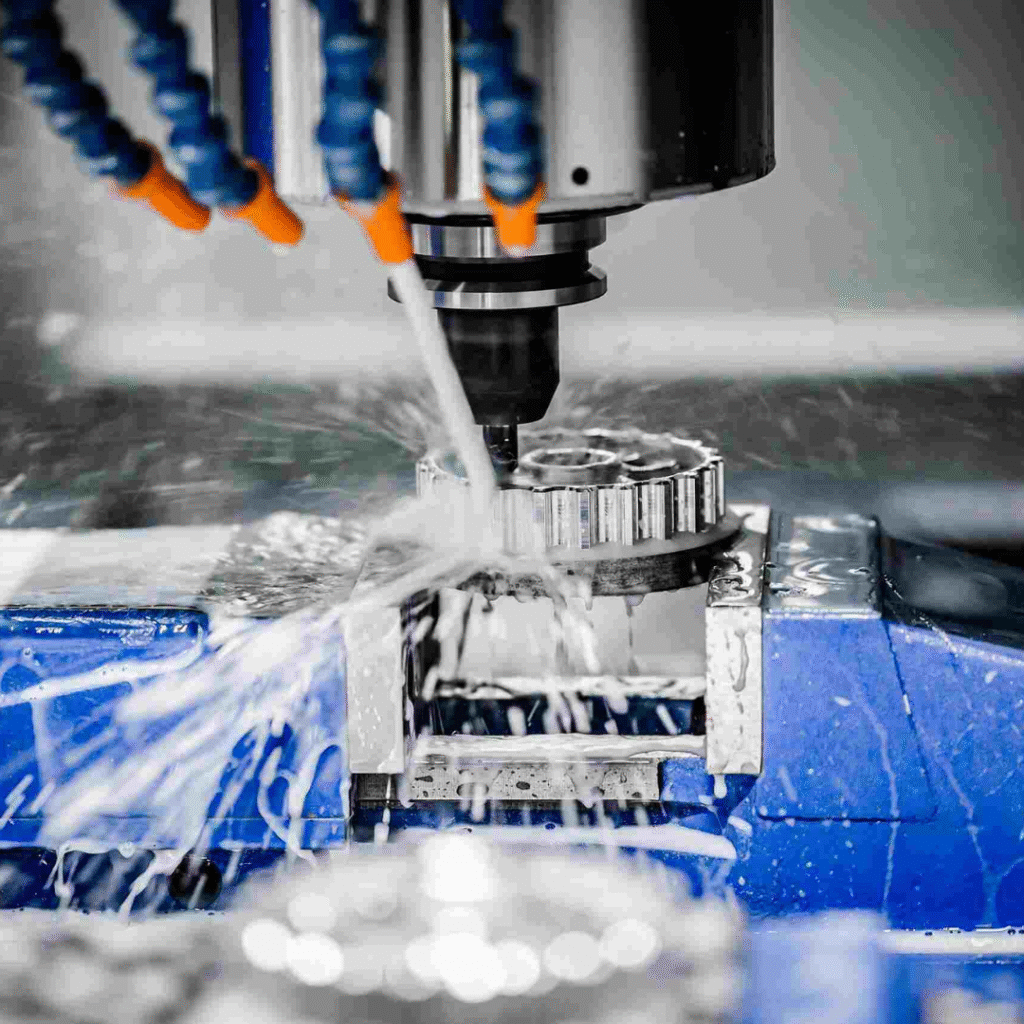

CNC Machining (Subtractive Manufacturing)

CNC machining removes material from a solid block (workpiece or blank) to create the final part. This is done with cutting tools, drills, and spinning mills controlled by computer programs.

Processes: CNC milling, CNC turning

Strengths: High accuracy, excellent surface finishes, tight tolerances

Materials: Metals, plastics, and wood

Best For: Functional parts with complex geometries, durability, and repeatability

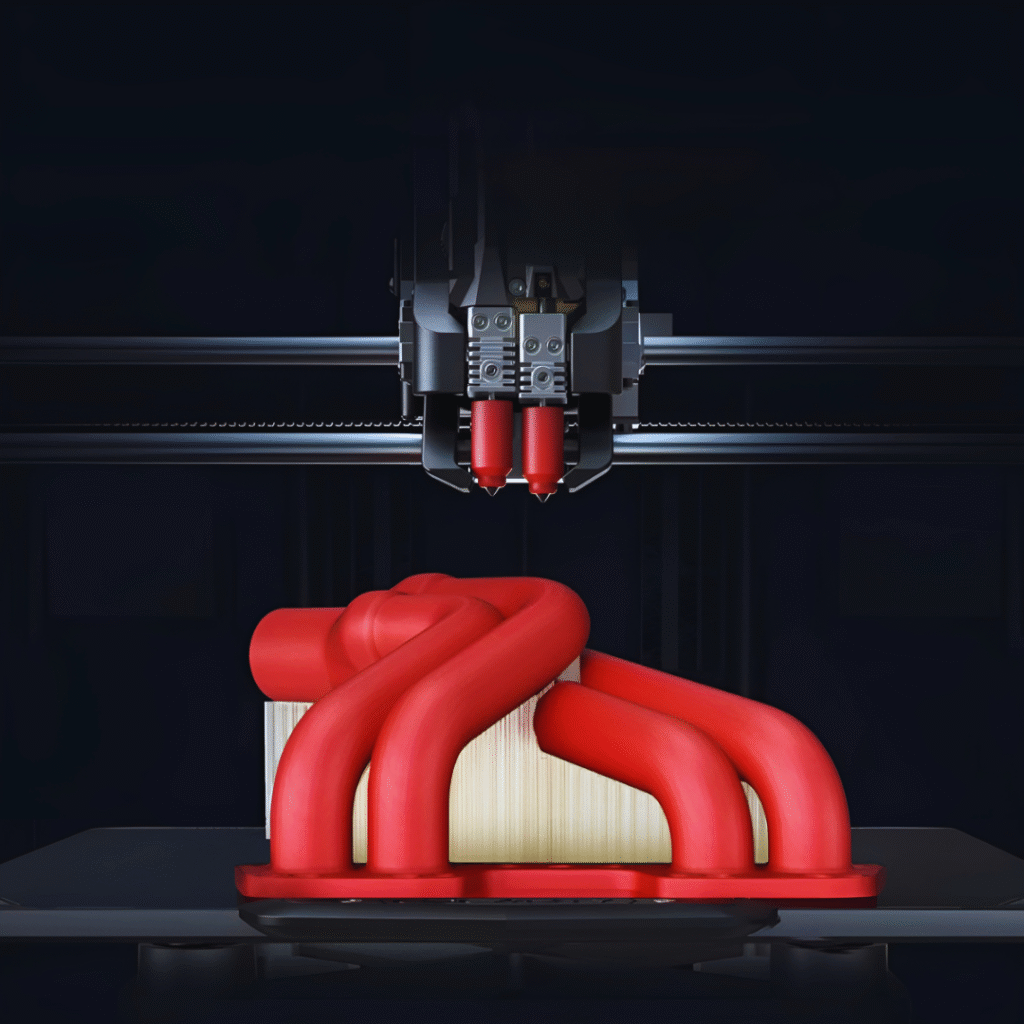

3D Printing (Additive Manufacturing)

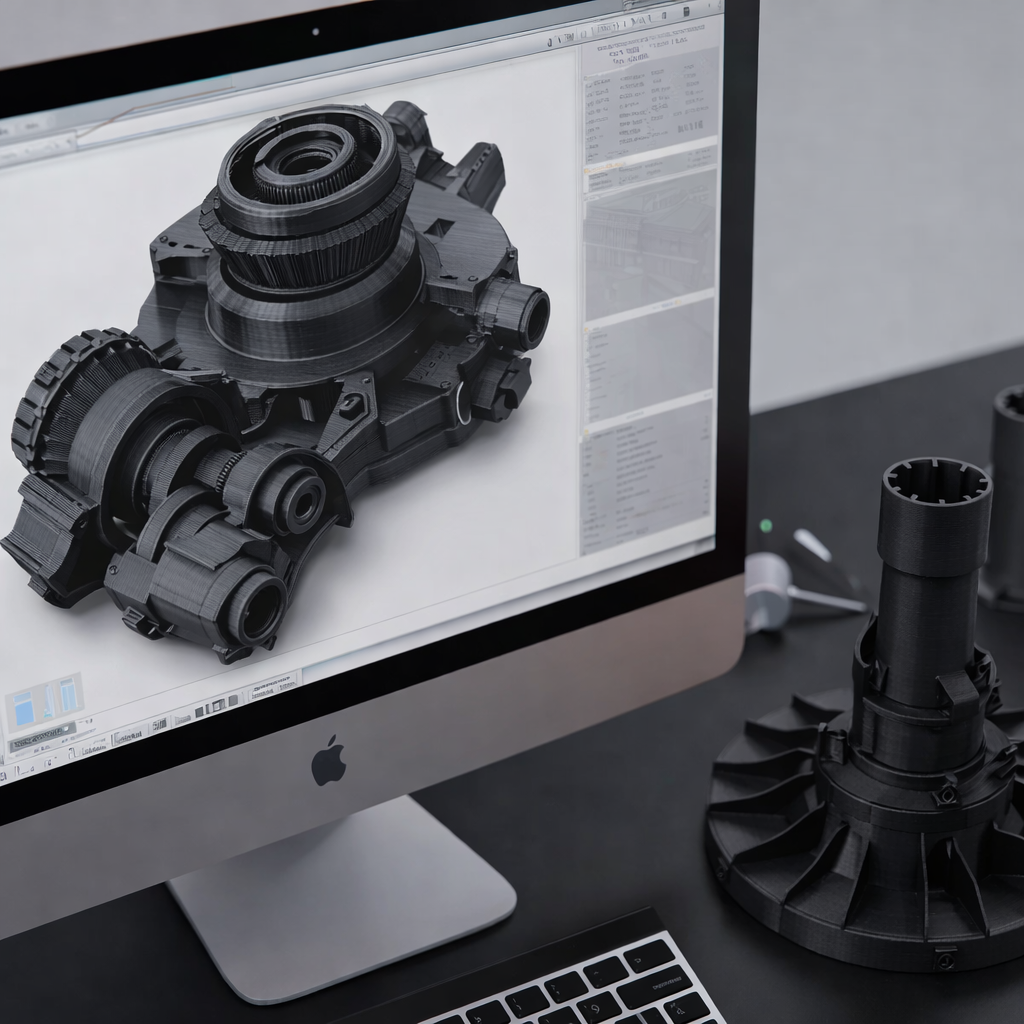

3D printing builds parts layer by layer directly from digital 3D models. Different processes use various raw materials, from filaments and resins to powders.

Processes:

FDM (filament extrusion – popular for hobbyists)

SLA/DLP/LCD (resin curing with UV light)

SLS/MJF/DMLS/SLM (powder bed fusion with lasers or heat)

Strengths: Design freedom, rapid prototyping, minimal waste

Materials: Thermoplastics, resins, metals, composites, ceramics

Best For: Complex geometries, lightweight parts, customized designs

Key Manufacturing Considerations

1. Materials

3D Printing: Mainly plastics (PLA, ABS, Nylon, ULTEM) and resins. Metal 3D printing (aluminum, stainless steel, titanium) is growing fast. Also supports advanced materials like ceramics and flexible polymers.

CNC Machining: Wide variety of plastics (PC, PMMA, PP, POM, PEEK, ABS, Nylon) and metals (aluminum, steel, titanium, brass, magnesium).

Takeaway: CNC offers broader compatibility with traditional materials, while 3D printing unlocks unique options like flexible polymers and lattice structures.

2. Physical Properties

Tolerance: CNC machining achieves tighter tolerances than 3D printing.

Surface Finish: CNC delivers smoother surfaces directly. 3D printed parts often require post-processing.

Size Limitations:

CNC: Limited by tool diameter (smallest detail)

3D Printing: Limited by build volume (largest size)

Temperature: Metals withstand higher temperatures; polymers and composites from 3D printing have lower thresholds.

Moisture Sensitivity: Some 3D printing filaments absorb water, affecting strength and print quality. CNC metals may rust in humid environments.

3. Economics

Speed:

CNC machining: Faster for medium/large parts since cutting speed isn’t heavily affected by part size.

3D printing: Faster for small or complex parts, especially when setup time is a factor.

Cost:

CNC machines are more expensive to purchase, operate, and maintain, requiring skilled operators.

3D printers are generally cheaper upfront, easier to set up, and better suited for low-volume runs.

Production Volume:

CNC machining is more cost-effective for medium-to-high volume due to reusable setups.

3D printing is ideal for prototypes, custom parts, and low-volume production.

Which Is Better?

There is no one-size-fits-all answer. Your decision should depend on:

Material requirements

Production volume

Budget and turnaround time

Complexity of design

For example:

Need hundreds of identical, durable parts? → CNC machining

Need a quick prototype or complex geometry with minimal waste? → 3D printing

This journey reminds us of why we do what we do. Innovation isn’t just about technology—it’s about people. It’s about listening to challenges, co-creating solutions, and relentlessly refining them until they make a real difference.

By empowering young innovators and turning their visions into reality, we’re not just building prototypes—we’re shaping the future.

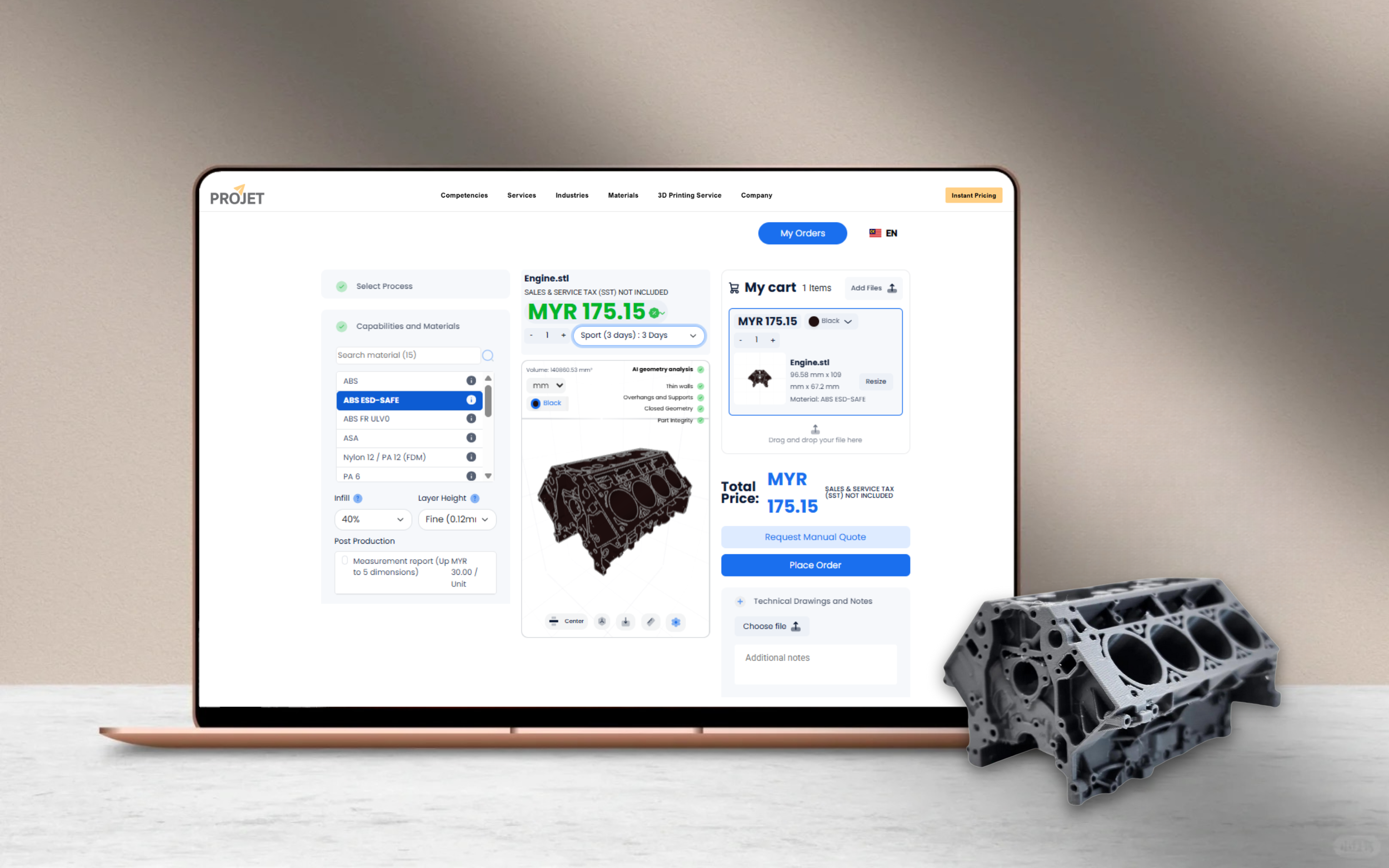

On-Demand Manufacturing with PROJET

At PROJET, we make it simple for you to choose the right manufacturing process.

CNC Services: CNC milling, CNC turning, and multiple surface finishes

3D Printing Services: SLA, SLS, MJF, and SLM metal 3D printing

How It Works: Upload your files (STL for 3D printing, STEP for CNC machining) to our instant quoting platform. Our team verifies printability and provides material and post-processing options.

We’re committed to turning your ideas into reality with precision, speed, and flexibility.

Contact us at enquiry@projet.my to get started today.

3D Printing Services

Instant Price