When are plastic materials suitable for machining projects?

When it comes to speed, CNC machining is faster for low-volume parts. It is an ideal short-term solution for smaller production goals, as mold fabrication can take anywhere from several weeks to a few months, leading to significant delays.

Among these, CNC machining and injection molding stand out as the two most widely used and most reliable for producing functional plastic components.

If you’re unsure which method fits your project, this guide breaks down the key differences, advantages, limitations, and ideal use cases for each—helping you choose the best process for your budget, timeline, and production volume.

Understanding the Processes

At the core, the two methods differ fundamentally:

CNC Machining

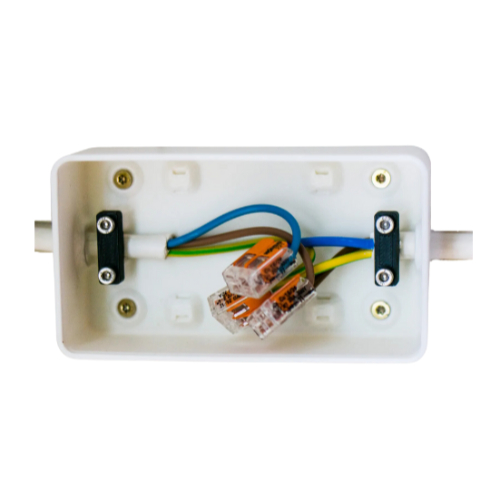

CNC machining starts with a solid block of plastic. A computer-controlled machine cuts away material layer by layer until the final shape is formed.

- Key benefits: high precision, excellent tolerances, and material flexibility.

Injection Molding

Injection molding melts thermoplastic pellets and injects them into a steel or aluminum mold. Once cooled, the part is ejected and the cycle repeats.

- Key benefits: extremely fast mass production and low cost per part at high volumes.

Speed & Lead Time

CNC Machining

- Faster for low-volume production

- Start producing parts immediately

- No mold required

- Perfect for prototyping or producing a few pieces up to a few hundred

Injection Molding

- Fastest option for mass production

- Mold fabrication takes weeks or months

- Once the mold is completed, production speed is extremely high (seconds per cycle)

- Ideal for continuous, high-volume manufacturing

Material Options

CNC Machining

- Offers the widest range of materials, including: Engineering plastics (POM, PEI, PEEK)

- High-strength polymers

- Filled composites

- Excellent for parts requiring high durability, heat resistance, or tight tolerances.

Injection Molding

- Works best with thermoplastics and thermoset resins that melt easily

- Not suitable for extremely hard or high-temperature plastics

- Common materials: ABS, PP, PC, Nylon, TPE, TPU

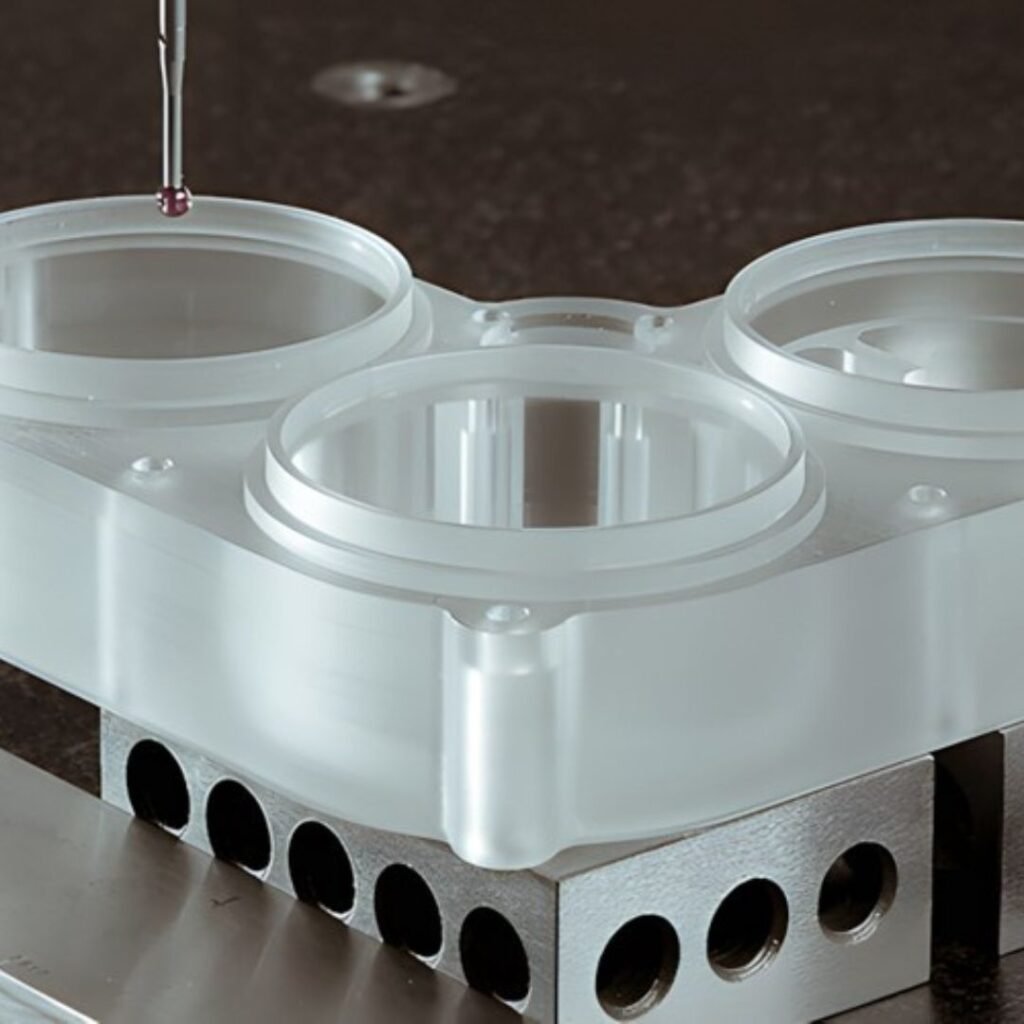

Tolerances & Precision

CNC Machining

- Superior accuracy and consistency

- Tight tolerances achievable (±0.01 mm)

- Ideal for:

– Functional prototypes

– Precision components

– Complex geometries requiring machining finesse

Injection Molding

- More prone to defects, such as:

– Warping

– Sink marks

– Flow lines

– Vacuum voids - Tolerances depend heavily on mold quality, cooling behavior, and part geometry.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Which Method Should You Choose?

Both CNC machining and injection molding have unique strengths. Choose based on what you need:

Choose CNC Machining if you need:

- Low-volume production

- Rapid prototyping

- Tight tolerances

- Strong material properties

- Design flexibility and fast revisions

Choose Injection Molding if you need:

- High-volume production

- Low cost per part

- Repeatability and consistency

- Complex molded features

- Long-term manufacturing scalability

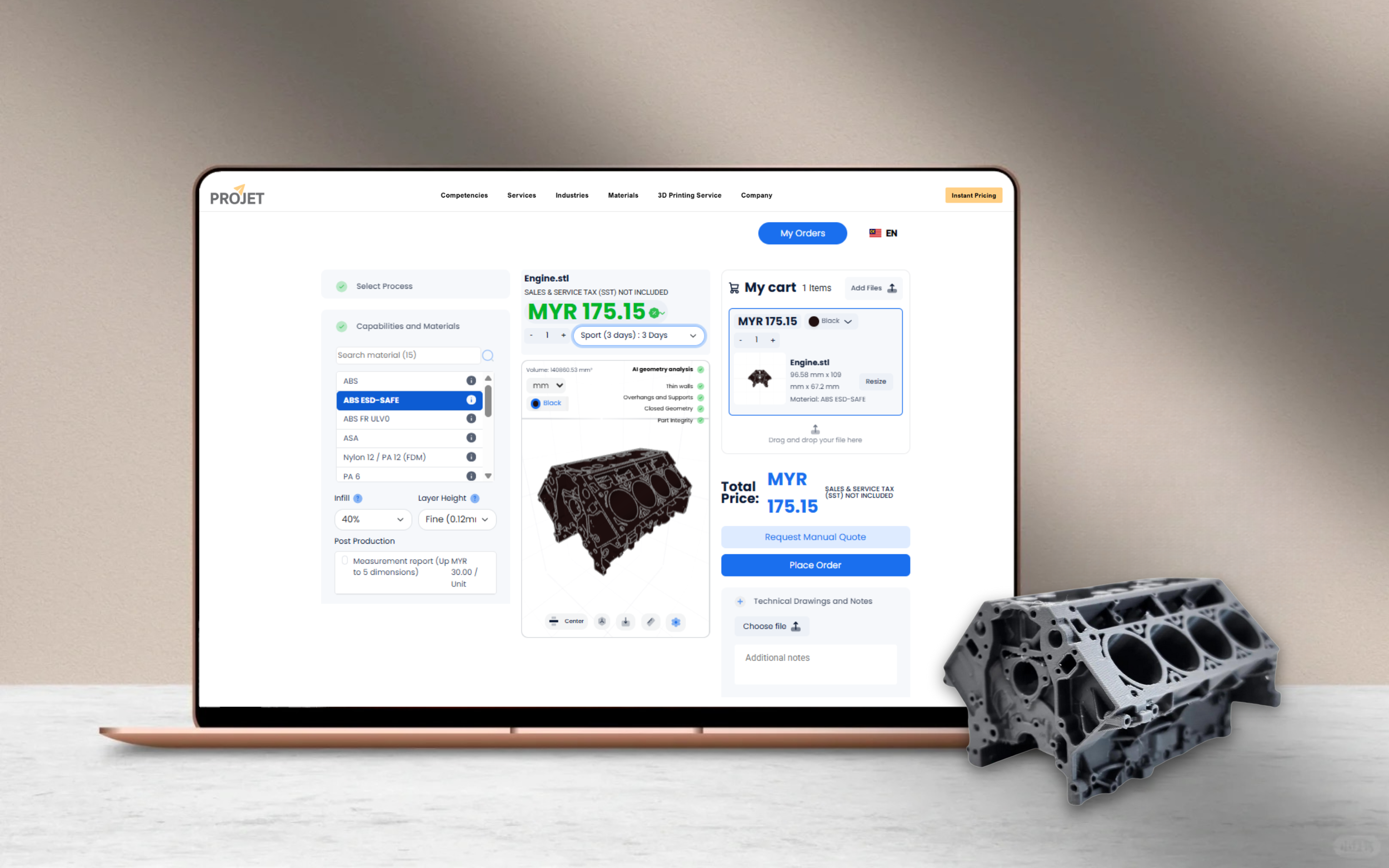

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success.

Here’s why companies across electronics, automotive, consumer products, aerospace, and medical industries trust Projet:

✔ One Stop Solution

✔ Engineering Expertise You Can Count On

✔ Flexible Production Volumes

✔ Fast Quotes & Rapid Turnaround

✔ Your Manufacturing Partner, Not Just a Supplier

3D Printing Services

Instant Price