How is Impact Resistance Measured?

Engineers rely on standardized tests to determine a plastic’s durability. When reviewing a manufacturer’s data sheet, look for these three key metrics:

Notched Izod Impact (ASTM D256): Measures the energy required to break a notched sample with a swinging pendulum.

Gardner Impact (ASTM D5420): Uses a falling weight to determine the energy required to cause failure.

Instrumented Dart Impact (ASTM D3763): A multiaxial test that simulates a high-speed strike to determine a material’s ductility.

Pro Tip: Strength and toughness are often contradictory. Greater tensile strength usually increases brittleness, while impact resistance requires a balance of strength and elongation at yield.

3 Common Impact-Resistant Materials

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is an opaque, amorphous polymer known for its extreme toughness, even at low temperatures. It is a staple in the automotive and consumer goods industries.

Key Features: Hard, rigid, and electrically insulative.

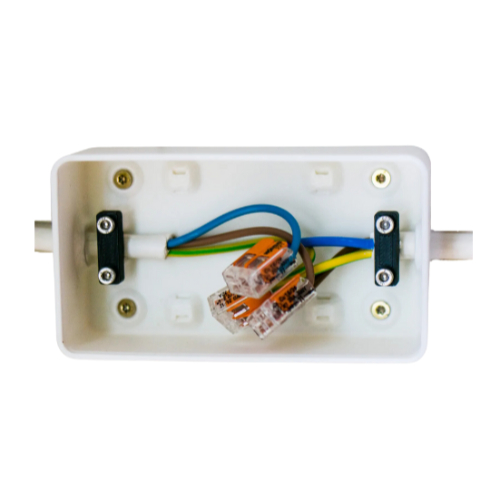

Applications: Dashboards, Lego bricks, and protective housings.

Limitation: Poor UV resistance and low fatigue life; not ideal for outdoor use without additives.

2. Polycarbonate (PC)

Polycarbonate is the gold standard for impact resistance—often referred to as “bulletproof glass.” It is the perfect balance of transparency and durability.

Key Features: High heat resistance, flame retardancy, and optical clarity.

Applications: Safety glasses, medical device housings, and riot shields.

Limitation: Susceptible to scratching (requires coating) and is more expensive than standard resins.

3. PETG (Polyethylene Terephthalate Glycol)

While PET is common for single-use bottles, PETG (glycol-modified) rivals polycarbonate for impact resistance at a much lower price point.

Key Features: Food-safe, biocompatible, and chemically resistant.

Applications: Medical packaging, instrument trays, and implants.

Limitation: Lower heat resistance compared to PC.

Environmental Factors: Why “Tough” Plastics Fail

A material that is impact-resistant in a lab may fail in the field due to environmental factors:

Temperature: Many polymers, like Polypropylene (PP), become brittle in cold temperatures (the “glass transition” effect).

UV Exposure: Plastics like Acetal (POM) and Polycarbonate (PC) can degrade and crack if left in the sun without UV stabilizers.

Chemical Exposure: Certain solvents can cause stress-cracking in otherwise tough materials like ABS.

Design Tips for Maximum Durability

Material choice is only half the battle. To prevent fracture, follow these design principles:

Radius Your Corners: Sharp internal corners act as “stress concentrators.” Always use generous fillets to distribute force.

Rib Placement: Place stiffening ribs in areas of compression rather than tension.

Allow for “Give”: A part that can flex slightly is less likely to shatter than a completely rigid one.

Manage Weld Lines: Ensure injection molding weld lines (where plastic flows meet) are located away from potential impact zones.

Mechanical Property Comparison: Impact Resistance vs. Strength

Material | Impact Resistance | Tensile Strength | Strength–Toughness Balance | Best Use Case |

ABS | High | Medium | Excellent toughness with moderate strength | Consumer product housings and automotive interiors requiring durability and cost efficiency |

Polycarbonate (PC) | Very High | High | Industry-leading impact resistance with high structural strength | Safety equipment, transparent guards, and medical enclosures exposed to impact |

PETG | High | Medium | Strong impact performance at lower cost than PC | Medical packaging, trays, and clear enclosures with moderate temperature exposure |

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success. Companies across the electronics, automotive, consumer products, aerospace, and medical industries trust Projet because we are more than just a supplier; we are a dedicated partner in their success.

Here’s what sets us apart:

A True One-Stop Solution

We provide a seamless experience by offering a comprehensive suite of manufacturing services under one roof. This integrated approach streamlines your supply chain and simplifies the journey from concept to a market-ready product.

Engineering Expertise You Can Count On

Our experienced engineering team acts as a dedicated extension of your own. We excel at solving complex manufacturing challenges and collaborate closely with you to optimize your designs for quality, cost-effectiveness, and manufacturability.

Flexible Production Volumes to Match Your Needs

Whether you require a single prototype or a high-volume production run, our manufacturing capabilities are designed to scale with your demands. We support your product’s entire lifecycle, from initial launch to full-scale production.

Rapid Turnaround for a Faster Time-to-Market

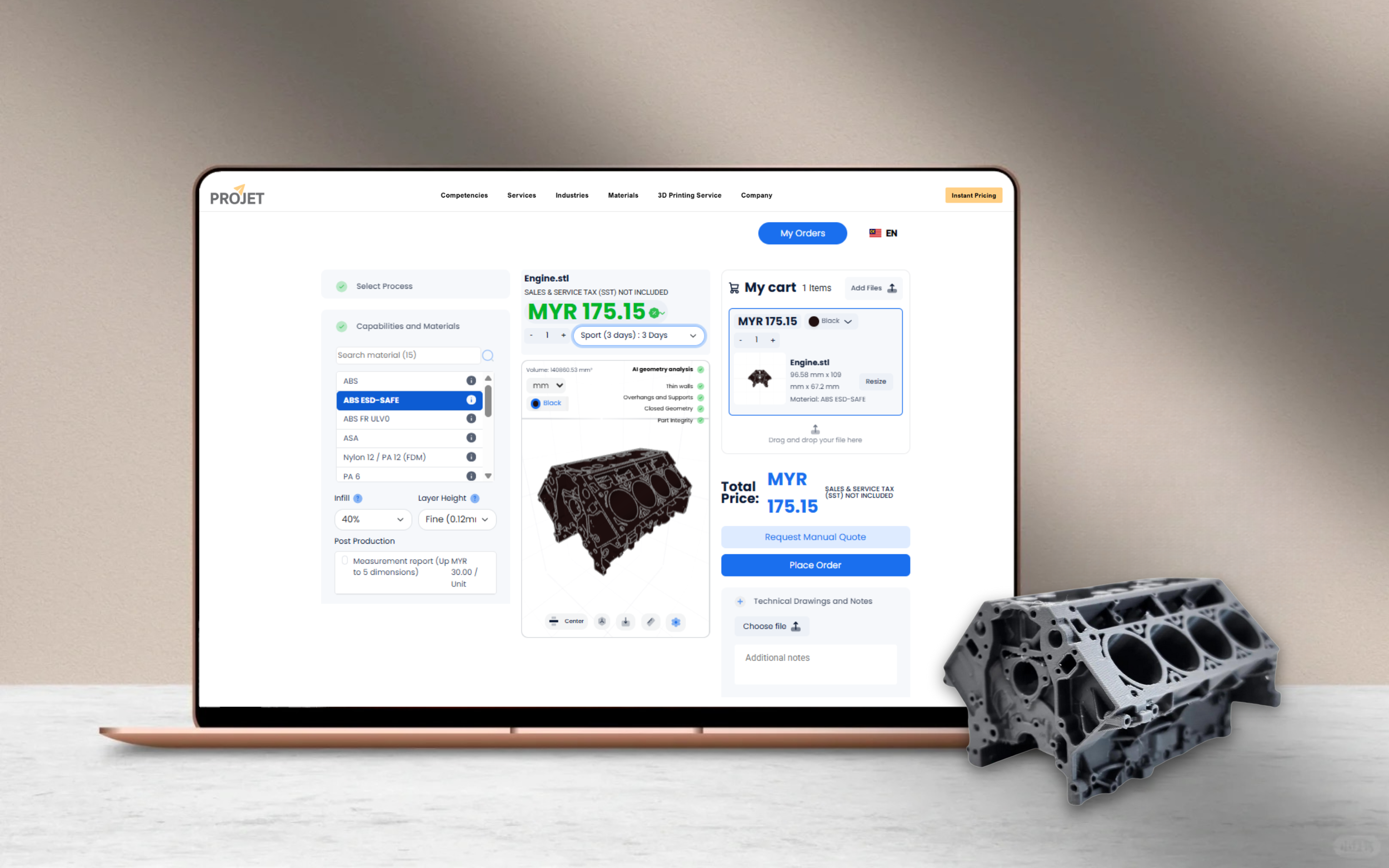

In today’s fast-paced market, speed is a crucial advantage. We deliver fast, transparent quotes and pride ourselves on our rapid turnaround times, helping you get your innovative products to market sooner.

3D Printing Services

Instant Price